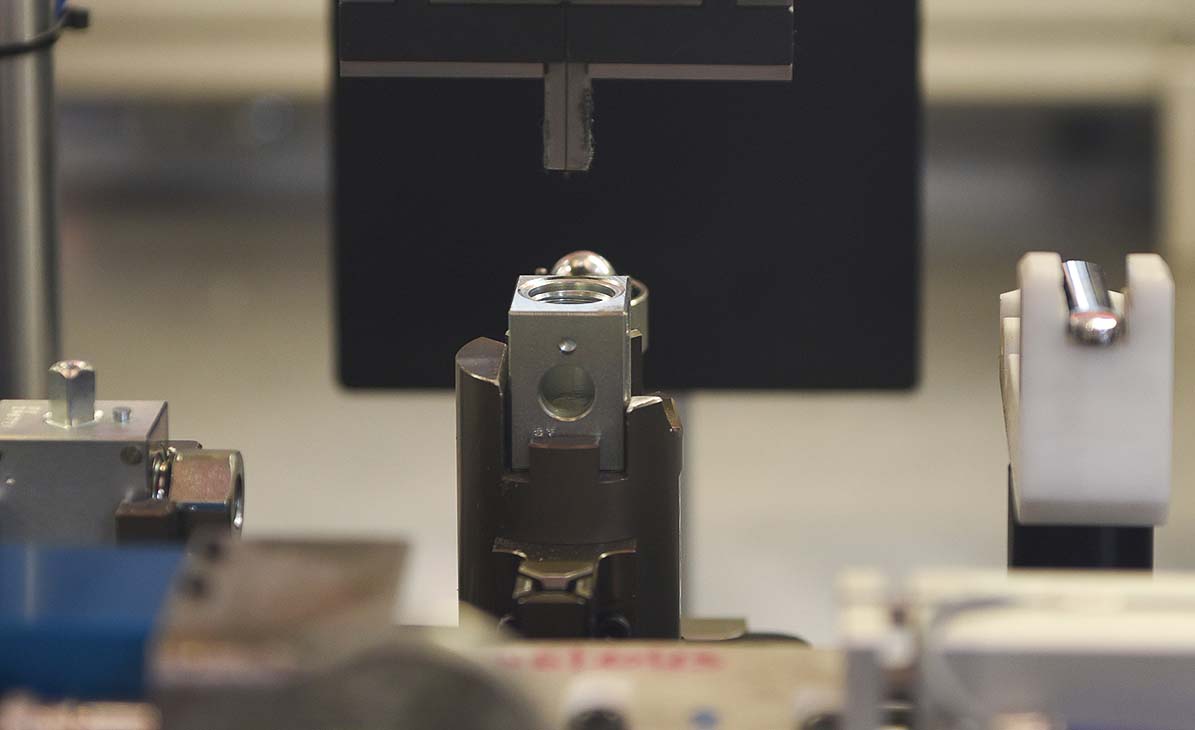

To ensure an additional quality guarantee, at the beginning of 2017 it was installed in our plant a new automatic assembly line for the mounting and testing of the ball valves. This machine permits the assembly and the relative test, of all the standard valves up to 1”. For each assembled valve it is done an automatic report that shows every step of the process, thanks to the pictures taken by the cameras placed in each station of the machine. For additional information about this automatic assembly line, it is possible to watch the video in the gallery section HERE. Besides this machine, there is the ‘historic’ manual assembly line for the fitting of the valves with bigger DN and of special models.

There is also the ‘historical’ manual assembly line for the assembly of special models and of big size ball valves up to 42”.

The whole production follows all the required standards, performing rigorous tests both after the production and the assembly.

After that, all valves are 100% tested using specific test benches.